Rapid deforestation threatening African development has a notable South African remedy gaining wider recognition and use, compressed soil bricks.

Rapid deforestation threatening African development has a notable South African remedy gaining wider recognition and use, compressed soil bricks.

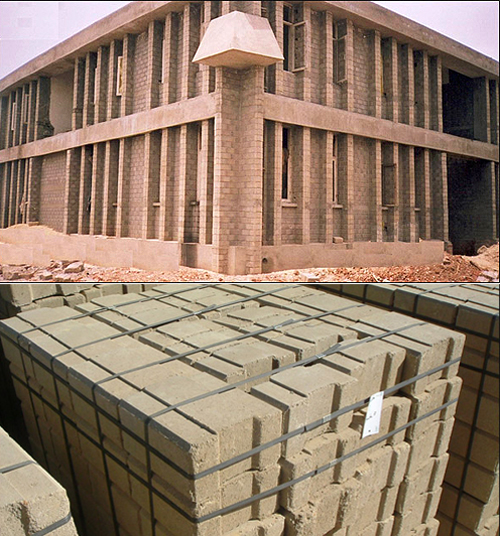

The process which has been known since the late 80s is only now gaining traction and some economic viability. Fairly expensive but remarkably mobile machines that operate on diesel or electricity compress soil and other ingredients like ash and cement into interlocking bricks that are assembled with no mortar or further fixatives.

Most of the machines can produce one brick every 14-15 seconds, thousands of times faster than traditional kilns.

The final structures are remarkably durable and sustainable, and greatly reduce the need for inorganic materials while totally replacing the fired kiln, thereby protecting forests.

The newest machine started production in Karatu, Tanzania, last week. The area has soil perfect for making bricks, although until now these were all fired in a kiln, threatening the forests around Ngorongoro Crater.

Introduced by a local NGO, Hifadhi Mazingira (HIMAKA), the bricks are sold at a quarter of the price of traditional fired bricks provided the consumer first plants a certain number of trees based on the size of his purchase of bricks.

“We imported the Hydra-form brick making machine from South Africa to produce bricks that can be sold at very low costs of 250/- per piece compared to the usual brick prices of 1000/- or more per brick,” the NGO’s founder told a local Arusha newspaper.

According to the South African manufacturer, 2500 bricks requires 10 liters of diesel. Carbon emissions compare favorably with the wood that would otherwise be required to fire the kiln for the same number of bricks, and the cost is much less.

According to an official of the Ngorongoro Conservation Area Authority most existing tourist lodges in the area used a minimum of 20 acres of trees to fire the kilns that created their bricks. As a result, new tourism initiatives are being directed to the interlocking hydraform bricks.

The product has found wide acceptance in India where the soil is appropriately “red” or heavily laced with copper, as in the case of Karatu, Tanzania.

Initiatives like these come to the fore when economies move them there. The price of wood in Tanzania has skyrocketed recently, because of rapid depletion. But whether hydraform bricks are really a better idea and more environmentally friendly than something else, like simple pressed wood or artificial fibers, it’s clearly a step seeking a right direction.

Hi Jim,

I am glad you mention this very promising and environmentally friendly way of making bricks; it will indeed make a huge different to the environment once it is accepted and adopted. Just a few additional comments, since we have started to introduce this new approach to our village:

These bricks can also be made by using a man-operated press making it even more environmentally friendly, adapted to village and remote situations and creating jobs or allowing for home use. Two trained people can churn out up to 400 bricks per day. For details have a look here: http://makiga.com/#/ground-breaker/4518370144

Building with these interlocking blocks does require a litte cement in any case, every 5th or 6th row should be built using a little cement, and then there are the concrete ring beams to consider. However, much less cement is used, and the building goes much faster. We built the first house with these bricks recently. To get the walls to ring beam level took 5 days, with conventional burnt bricks it woud have taken at least double the time. The result is that the shorter employment of a mason further contributes to reducing costs.

The challenge remaining is to convince people that this new way of building is indeed worth it, and that structures using these bricks are at least as durable as structures built with traditional bricks.